Se latelang ke ts'ebetso e felletseng ea tlhahiso ho tloha ho SMT (theknoloji ea holimo holimo) ho ea ho DIP (sephutheloana sa li-in-line tse peli), ho fumana AI le ASSY (kopano), le basebetsi ba theknoloji ba fanang ka tataiso nakong eohle ea ts'ebetso. Ts'ebetso ena e akaretsa lihokelo tsa mantlha tsa tlhahiso ea elektroniki ho netefatsa tlhahiso ea boleng bo holimo le e sebetsang hantle.

Qetella ts'ebetso ea tlhahiso ho tsoa ho SMT→DIP→I tlhahlobo→ASSY

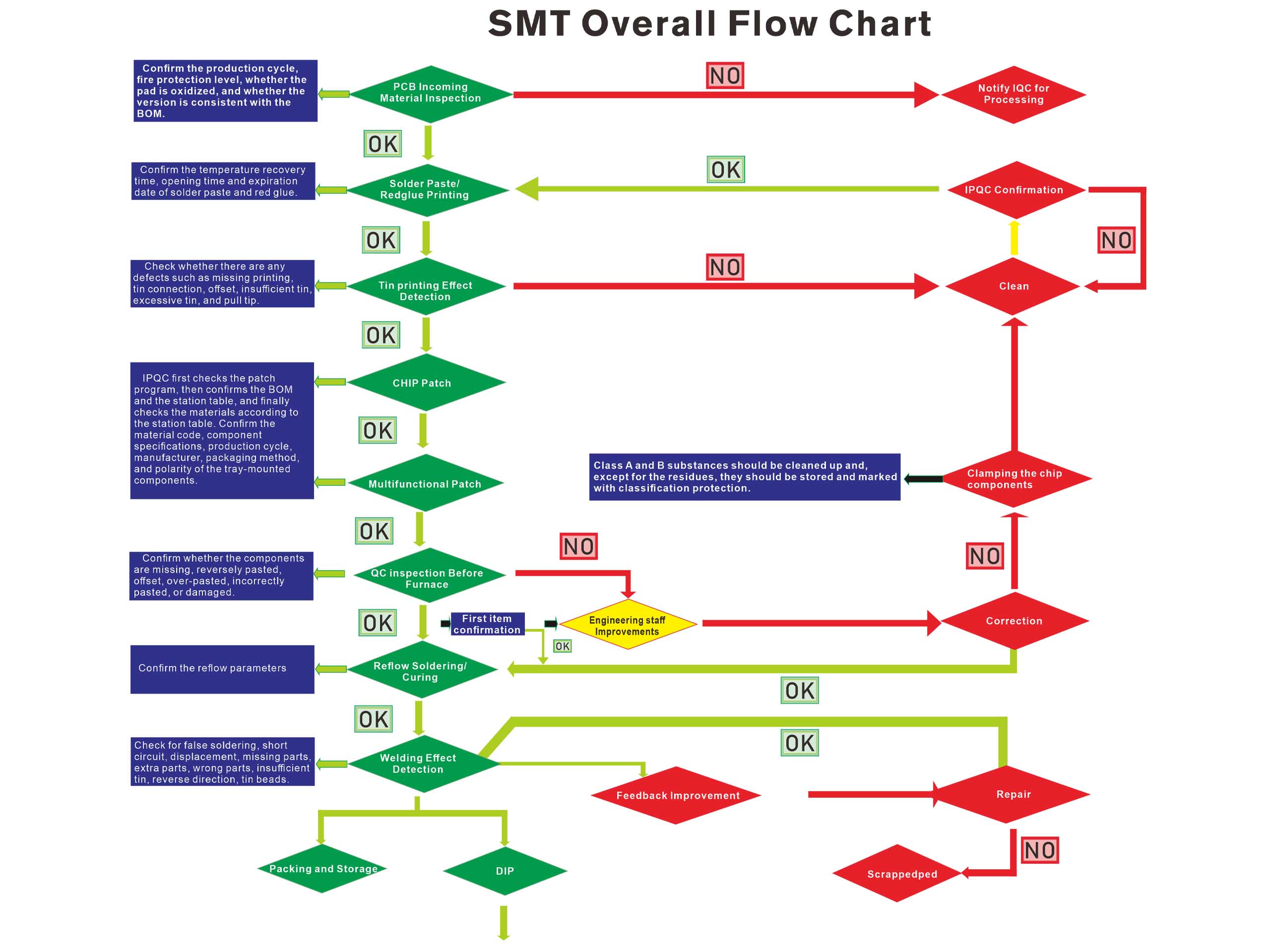

1. SMT (theknoloji ea holim'a marulelo)

SMT ke ts'ebetso ea mantlha ea tlhahiso ea elektronike, e sebelisoang haholo ho kenya likarolo tsa holim'a metsi (SMD) ho PCB.

(1) Khatiso ea solder paste

Thepa: printa ea solder paste.

Mehato:

Lokisa PCB bencheng ea mosebetsi ea khatiso.

Hatisa pente ea solder ka nepo holim'a liphahlo tsa PCB ka letlooeng la tšepe.

Lekola boleng ba khatiso ea solder paste ho netefatsa hore ha ho na offset, khatiso e sieo kapa khatiso e fetelletseng.

Lintlha tsa bohlokoa:

The viscosity le botenya ba solder peista lokela ho kopana ditlhoko.

Mesh ea tšepe e hloka ho hloekisoa khafetsa ho qoba ho koala.

(2) Ho beha likarolo

Thepa: Mochini oa ho Khetha le ho Beha.

Mehato:

Kenya likarolo tsa SMD ka har'a sesebelisoa sa mochini oa SMD.

Mochini oa SMD o nka likarolo ka nozzle ebe o li beha ka nepo sebakeng se boletsoeng sa PCB ho latela lenaneo.

Lekola ho nepahala ha ho beoa ho netefatsa hore ha ho na offset, likarolo tse fosahetseng kapa likarolo tse sieo.

Lintlha tsa bohlokoa:

Polarity le tataiso ea likarolo li tlameha ho nepahala.

Nozzle ea mochini oa SMD e hloka ho bolokoa khafetsa ho qoba tšenyo ea likarolo.

(3) Reflow soldering

Thepa: Sebōpi sa solder sa Reflow.

Mehato:

Romela PCB e kentsoeng ka seboping sa solder sa reflow.

Ka mor'a mekhahlelo e mene ea ho futhumatsa pele, mocheso o sa khaotseng, ho phalla le ho pholile, pente ea solder e qhibiliha 'me motsoako o ka tšeptjoang oa solder o thehoa.

Lekola boleng ba solder ho netefatsa hore ha ho na liphoso tse kang li-solder tse batang, borokho kapa majoe a mabitla.

Lintlha tsa bohlokoa:

Mocheso oa mocheso oa "reflow soldering" o hloka ho ntlafatsoa ho latela litšoaneleho tsa solder paste le likaroloana.

Lekanya mocheso oa sebōpi khafetsa ho netefatsa boleng bo tsitsitseng ba tjheseletsa.

(4) Tlhahlobo ea AOI (tlhahlobo ea optical e iketsang)

Thepa: sesebelisoa sa ho hlahloba ka mokhoa o itekanetseng (AOI).

Mehato:

Optically skena PCB e rekisoang ho bona boleng ba manonyeletso a solder le ho nepahala ha karolo e ntseng e eketseha.

Rekota le ho sekaseka liphoso le maikutlo mabapi le ts'ebetso e fetileng bakeng sa ho lokisoa.

Lintlha tsa bohlokoa:

Lenaneo la AOI le hloka ho ntlafatsoa ho latela moralo oa PCB.

Lekola lisebelisoa khafetsa ho netefatsa hore li nepahetse.

2. Ts'ebetso ea DIP (sephutheloana sa li-in-line tse peli).

Ts'ebetso ea DIP e sebelisoa haholo-holo ho kenya likarolo tsa ka-hole (THT) 'me hangata e sebelisoa hammoho le ts'ebetso ea SMT.

(1) Kenyelletso

Thepa: mochini o kenyang letsoho kapa oa othomathike.

Mehato:

Kenya karolo ea ka-hole sebakeng se boletsoeng sa PCB.

Hlahloba ho nepahala le botsitso ba ho kenya karolo.

Lintlha tsa bohlokoa:

Lithakhisa tsa karolo li hloka ho fokotsoa ho ea bolelele bo loketseng.

Etsa bonnete ba hore karolo ea polarity e nepahetse.

(2) Wave soldering

Lisebelisoa: sebōpi sa solder sa wave.

Mehato:

Beha plug-in PCB ka seboping sa wave soldering.

Solder karolo ea likhoele ho lipache tsa PCB ka ho soahla ka maqhubu.

Lekola boleng ba solder ho netefatsa hore ha ho na manonyeletso a batang a solder, borokho kapa manonyeletso a lutlang a solder.

Lintlha tsa bohlokoa:

Mocheso le lebelo la solder ea wave li hloka ho ntlafatsoa ho latela litšobotsi tsa PCB le likaroloana.

Hloekisa bate ea solder khafetsa ho thibela litšila ho ama boleng ba solder.

(3) Soldering ka letsoho

Ka bowena lokisa PCB ka mor'a leqhubu soldering ho lokisa mefokolo (tse kang batang solder manonyeletso le borokho).

Sebelisa tšepe ea tšepe kapa sethunya sa moea o chesang bakeng sa solder ea sebakeng seo.

3. Ho lemoha ha AI (ho lemoha bohlale ba maiketsetso)

Tlhahlobo ea AI e sebelisoa ho ntlafatsa ts'ebetso le ho nepahala ha tlhahlobo ea boleng.

(1) Ho lemoha pono ea AI

Lisebelisoa: Sistimi ea ho lemoha pono ea AI.

Mehato:

Nka litšoantšo tsa boleng bo holimo tsa PCB.

Sekaseka sets'oants'o ka li-algorithms tsa AI ho tseba bofokoli ba soldering, component offset le mathata a mang.

Hlahisa tlaleho ea teko 'me u e fepe hape molemong oa tlhahiso.

Lintlha tsa bohlokoa:

Mohlala oa AI o hloka ho koetlisoa le ho ntlafatsoa ho ipapisitsoe le data ea sebele ea tlhahiso.

Ntlafatsa algorithm ea AI khafetsa ho ntlafatsa ho nepahala ha tlhahlobo.

(2) Tlhahlobo ea ts'ebetso

Thepa: Thepa ea tlhahlobo e ikemetseng (ATE).

Mehato:

Etsa liteko tsa ts'ebetso ea motlakase ho PCB ho netefatsa mesebetsi e tloaelehileng.

Ngola liphetho tsa liteko 'me u hlahlobe lisosa tsa lihlahisoa tse nang le bothata.

Lintlha tsa bohlokoa:

Mokhoa oa tlhahlobo o hloka ho raloa ho latela litšobotsi tsa sehlahisoa.

Kamehla lekanya lisebelisoa tsa tlhahlobo ho netefatsa bonnete ba tlhahlobo.

4. Mokhoa oa ASSY

ASSY ke mokhoa oa ho kopanya PCB le likarolo tse ling hore e be sehlahisoa se felletseng.

(1) Kopano ea mechine

Mehato:

Kenya PCB ka tlung kapa bracket.

Hokela likarolo tse ling joalo ka likhoele, likonopo, le li-skrini tsa ponts'o.

Lintlha tsa bohlokoa:

Etsa bonnete ba hore kopano e nepahetse ho qoba tšenyo ea PCB kapa likarolo tse ling.

Sebelisa lisebelisoa tsa anti-static ho thibela tšenyo e tsitsitseng.

(2) Ho chesoa ha software

Mehato:

Chesa firmware kapa software mohopolong oa PCB.

Sheba liphetho tse tukang ho netefatsa hore software e sebetsa ka mokhoa o tloaelehileng.

Lintlha tsa bohlokoa:

Lenaneo le tukang le tlameha ho lumellana le mofuta oa hardware.

Netefatsa hore tikoloho e tukang e tsitsitse ho qoba litšitiso.

(3) Tlhahlobo ea mochine o feletseng

Mehato:

Etsa liteko tse sebetsang ho lihlahisoa tse kopaneng.

Hlahloba ponahalo, tshebetso le ho tšepahala.

Lintlha tsa bohlokoa:

Lintlha tsa tlhahlobo li tlameha ho akaretsa mesebetsi eohle.

Rekota lintlha tsa liteko 'me u hlahise litlaleho tsa boleng.

(4) Ho paka le ho romelloa

Mehato:

Packaging ea anti-static ea lihlahisoa tse tšoanelehang.

Label, paka 'me u itokisetse ho romelloa.

Lintlha tsa bohlokoa:

Sephutheloana se tlameha ho fihlela litlhoko tsa lipalangoang le polokelo.

Rekota lintlha tsa thomello hore li fumanehe habonolo.

5. Lintlha tsa bohlokoa

Taolo ea tikoloho:

Thibela motlakase o sa fetoheng 'me u sebelise lisebelisoa le lisebelisoa tsa anti-static.

Tlhokomelo ea lisebelisoa:

Kamehla hlokomela le ho lekanya lisebelisoa tse joalo ka bahatisi, mechini ea ho bea, lionto tsa reflow, lionto tsa wave soldering, jj.

Ntlafatso ea ts'ebetso:

Ntlafatsa mekhoa ea ts'ebetso ho latela maemo a sebele a tlhahiso.

Taolo ea boleng:

Ts'ebetso e 'ngoe le e' ngoe e tlameha ho hlahlojoa ka mokhoa o tiileng oa boleng ho netefatsa chai.